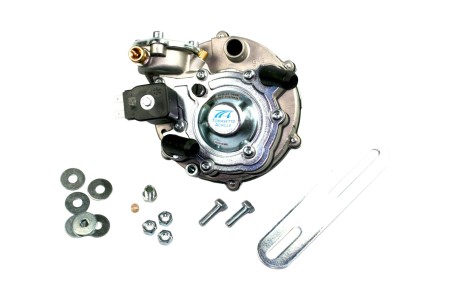

LPG reducer

LPG reducer - functioning, symptoms and repair

How does the LPG reducer work?

A reducer is one of the most important components of an LPG autogas system. Its task is to transfer the cold LPG gas from the tank from the liquid phase to the gas form, and at the same time to lower the pressure from about 10 bars to 1-2 bars working pressure. The LPG autogas reducer is also called pressure reducer and is necessary to reduce the pressure and safely supply the LPG to the engine via the LPG injectors.

To perform this process, it requires energy in the form of heat, which is provided by the waste heat via the engine coolant. Therefore, the LPG reducer is also heat exchanger to see.

In general, reducers of an LPG conversion kit have a two-chamber system, which is separated by a rubber membrane. The LPG reducer is connected to the cooling water circuit of the vehicle to bring the reducer to temperature by the warm cooling water. Liquid LPG flows through the second chamber, which is heated, thereby vaporizing and converting it to the gas phase. The reducer requires a certain working pressure, which can be set on most reducers via a regulating screw.

The most important thing to know about the reducer is that it must be completely tight at all times and should not have any leaks. Otherwise, the necessary working pressure can not be maintained. If the gunmi membrane leaks, the LPG fuel could mix with the cooling water and this could lead to engine damage in the worst case.

Vaporizers of LPG conversion kits usually have a KW specification, which is based on the engine power of the vehicle to be converted. The KW specification of the LPG reducer should be understood as an upper limit to be able to ensure a durable and safe operation of the vehicle.

Among the most common LPG reducers include Prins reducers, BRC reducers, KME, Landi Renzo, Zavoli, Lovato, Tartarini, etc.

With repair kits, high-quality reducers from Prins, BRC, Landi Renzo and other manufacturers can be repaired at low cost. In any case, the repair should be carried out by a professional.

Symptoms LPG reducer defective

A defective reducer often has various causes, including poor gas quality, which leads to sticking of the reducer, incorrect installation or a defective rubber membrane.

Because the reducer must maintain a constant working pressure for safe operation, problems such as contamination/ sticking or leakage will cause the LPG reducer to be unable to maintain a constant working pressure. Depending on the problem, the pressure of the reducer rises or falls, causing the LPG conversion kit to shut down and the vehicle to switch back to gasoline operation. Switching back to gasoline mode is controlled by the gas control unit.

A special feature of Prins LPG conversion kits is that if there are problems with the reducer when switching back to gasoline mode, a 10-minute lock is activated, which ensures that the vehicle can no longer be switched back to gas mode by the driver. If the 10-minute lockout has expired and you try to switch the vehicle back to gas mode, but the evaporator pressure is still too high or too low, the same error message becomes active again and the 10-minute lockout takes effect again. Thus, one can limit very well by remote diagnosis problems with the evaporator in Prins LPG conversion kits.

Prins evaporators of the first generation which were equipped with two membranes, often had the problem that with a defective reducer the gas has penetrated into the coolant circuit. This was very dangerous for the engine, because gas with approx. 10bar pressure penetrated into the coolant circuit, which works with approx. 2bar. When troubleshooting why the pressure in the coolant circuit increased, in most cases it was not obvious that the reducer was the cause of the problem. As a result, the cylinder head gasket was replaced at great expense without having eliminated the cause.

In newer generations of Prins reducers with modified design, these problems no longer appeared.

If a defective reducer is suspected, the lid of the expansion tank can be opened to check whether gas odor can be heard.

Sticking of the reducer due to poor gas quality

By inferior gas quality can lead to deposits in the LPG reducer, which in turn can cause it to stick. A gummed reducer can no longer be regulated and can no longer keep the pressure constant. As a result, the LPG conversion kit switches back to gasoline operation.

In any case, the reducer must be checked by a professional to ensure that it is working properly. Either the reducer must be replaced or the inner workings can be completely revised by using a repair kit.

Vaporizer problems due to installation errors

The incorrect installation of the LPG reducer is a common cause of problems with the LPG autogas system. It must be properly integrated into the cooling circuit so that it reaches a sufficiently high temperature (about 70 - 90 degrees Celsius or higher) to convert the liquid LPG into the low-pressure gas phase. If the reducer is not properly installed, it will not be able to reach the necessary temperature and this will subsequently cause, for example, the reducer pressure to be too high, causing the gas control unit to switch the system back to gasoline mode.